PHOTOMICROMETER 3D

HARDWARE AND SOFTWARE COMPLEX

FOR HIGH PRECISION THREE-DIMENSIONAL MONITORING

OF CRACKS, CLEARANCE AND EXPANSION JOINTS

The photogrammetric crack-metering device (photo crack meter, in short) is a hardware and software complex for high precision three-dimensional monitoring of cracks, clearance and expansion joints.

TECHNOLOGY ADVANTAGES

-

Remote measurement method

Remote measurement method -

High precision (up to 0.005 mm)

High precision (up to 0.005 mm) -

Obtaining offset values along three coordinate axes

Obtaining offset values along three coordinate axes -

Full automation of the process

Full automation of the process -

Visualizing Time Offset Values

Visualizing Time Offset Values -

Low cost of components

Low cost of components

Composition

MAIN COMPONENTS OF THE photo crack meter COMPLEX

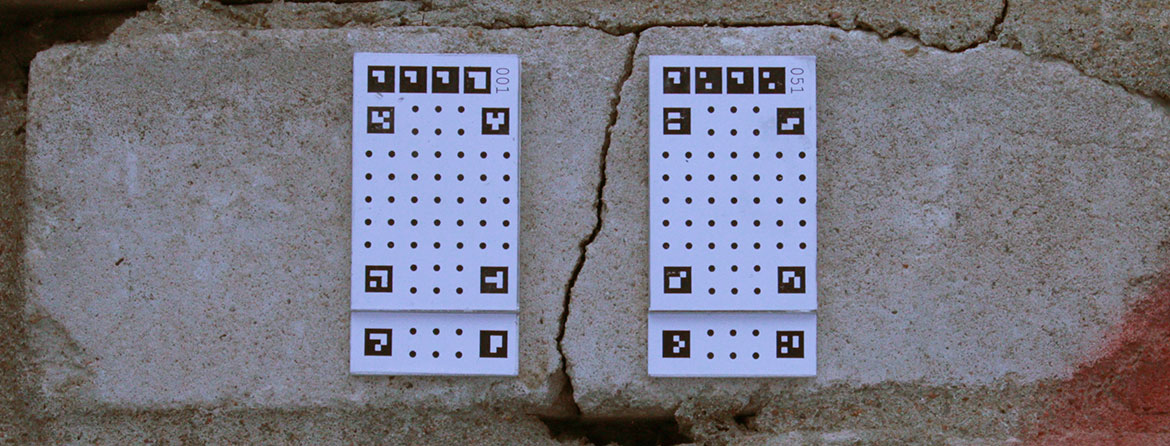

Photogrammetric marker

set of pair of photogrammetric markers

Set of pair of photogrammetric markers - special pictures with unique numbers, printed on the plate, which are fixed along both sides of a crack or an expansion joint

The photogrammetric marker is one of the three main components of the system, which performs the following main functions:

- fixing the monitoring site;

- setting the scale and coordinate system of monitoring;

- contains initial data for photogrammetric calibration of images.

TYPES OF MARKERS

(classification by accuracy, materials of production, mounting methods)

The modern camera

any modern camera

Any modern camera with the optical zoom required for certain shooting conditions.

The system is organized in such a way that all images undergo photogrammetric calibration during processing.

This makes it possible to use any modern photo or video camera for monitoring (from a phone to expensive mirror equipment) and get high-quality results.

Camera requirements. Basic photographing principles.

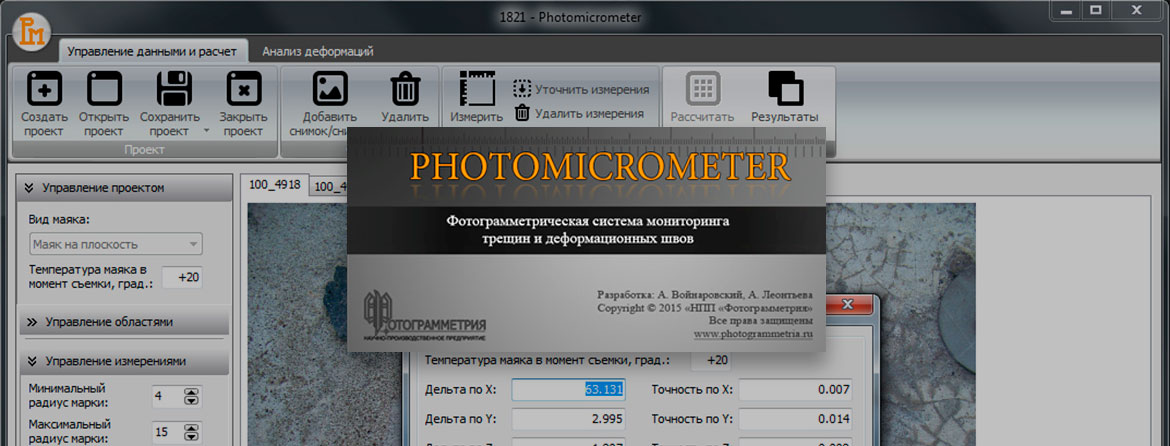

“PhotoMicrometer” SOFTWARE

Development of the company

The PhotoMicrometer system is based on theoretically rigorous photogrammetry methods: high-precision markers measurement algorithm, forward and reverse photogrammetric serifs with simultaneous calibration of images and equalization of the determined parameters using the least squares method.

PhotoMicrometer can be used for processing of both single images (photogrammetric method) and multiple images (stereophotogrammetric method). The program supports processing of various types photo markers (accuracy classes), rebuilding the interface taking into account this parameter.

Operating principles, data organization, results of calculations and their estimates.

Operating principles

SYSTEM ADAPTED FOR SPECIALIST APPLICATIONS

INSPECTION AND OPERATION OF BUILDINGS AND STRUCTURES

DOES NOT REQUIRE SPECIAL PHOTOGRAMMETRY KNOWLEDGE

The PhotoMicrometer system is based on theoretically rigorous photogrammetry methods: high-precision markers measurement algorithm, forward and reverse photogrammetric serifs with simultaneous calibration of images and equalization of the determined parameters using the least squares method. Thanks to the theoretically rigorous and technically advanced algorithms of the solution, almost any digital camera can be used to work with the system. At the same time, there is no need to pre-calibrate it. PhotoMicrometer can be used for processing of both single images (photogrammetric method) and multiple images (stereophotogrammetric method). The program supports processing of various types photo markers (accuracy classes), rebuilding the interface taking into account this parameter.

SPECIFICATIONS

DEFINITIVE INDICATORS OF THE PhotoMicrometer system

The size of the determined deformations or displacements:

from 0 to 10 cm along each of the coordinate axes (with mutual displacements of the beacons exceeding 3 cm, certain rules must be observed when shooting).

more details...

Accuracy of determining spatial displacements and deformations:

from 0.005 to 0.02 mm (depends on the distance and shooting angles, camera parameters). The results of assessing the accuracy of photogrammetric determinations are given in the report generated by the program.

more details...

Shooting Distances:

there is no need to use car towers and other lifting devices to make accurate measurements, you can shoot from a distance: photogrammetric method - from 0.1 to 0.3 m; stereophotogrammetric method - from 0.1 to 40 m.

more details...

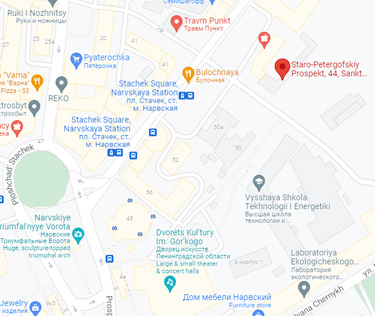

CONTACT INFORMATION

Saint-Petersburg,

190020, RF

Phone number:

tel: +7 (812) 992-26-85

tel/fax: +7 (812) 252-02-08

write to us

PRICE

SPECIFICATION

of the supplied equipment and software those are parts of the photogrammetric complex Photo crack meter,

developed for monitoring cracks and expansion joints in buildings and structures.

M-0.1 (2 pcs.) for installation on both sides of the crack

Accuracy of determining deformations or displacements on each coordinate axis — 0.1 mm (MSE)

Completed with calibration file.

20 euro

CheckoutM-0.02 (2 pcs.) for installation on both sides of the crack

Accuracy of determining deformations or displacements on each coordinate axis — 0.02 mm (MSE)

Completed with calibration file.

35 euro

CheckoutM-0.005 (2 pcs.) for installation on both sides of the crack

Accuracy of determining deformations or displacements on each coordinate axis — 0.005 mm (MSE)

Completed with calibration file.